STEAM TO ENERGY Transformer

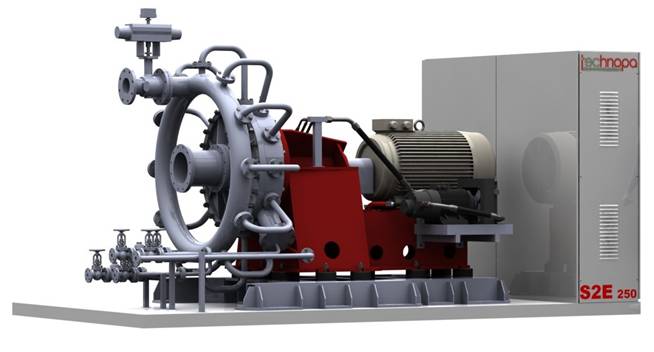

Micro Steam Turbine & Generator Module

Wet Steam Turbine Operation

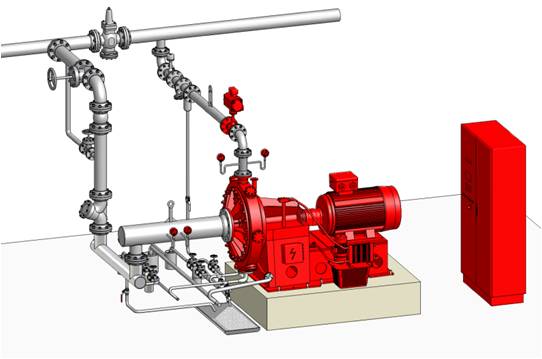

PLUG and PRODUCE System

Key Features

- High efficient, steam based energy generator

- Efficient operation in the conditions of wet steam

- Excellent ratio power/weight

- Modular construction with simple installation

- Environmental friendly technology

- Fully usable clean output steam

- Working life min. 100 000 hours

- Full power reaction time in 10 minutes

Technical parameters

| Characteristics | Specification |

| Electric Power 50-500 kWe |

50 – 200 kWe |

| Incoming steam temperature | min 130 °C max 350 °C |

| Incoming pressure | min 4,0 bar Abs. max 35,0 bar Abs. |

| Outcoming steam temperature | min 105 °C max 315 °C |

| Outcoming steam pressure | min 1,1 bar Abs. max 6,0 bar Abs. |

| Steam flow | min 1,1-3 t/hour max 20 t/hour |

If you have other parameters , please contact TECHNOPA

technical service

Electric parameters

| Characteristics | Specification |

| Voltage 50-500 kWe |

230V 480VAC /400VAC |

| Frequency | 50 Hz / 60 Hz |

| Grid-isolated regulation / steady state / |

+/- 0,50 % nominal voltage max +/- 0,50 % nominal frequency |

| Isolation class | IP 55, IP 42 |

S2E System – No Gear Box – Low Service Costs

Complete Installation Service SupportIncluded

Minimum Clearence Requirements

| Dimension | Size |

| Vertical | 2000 mm |

| Horizontal front, and rear side | 2000 mm |

| Horizontal left OR right side | 3000 mm |

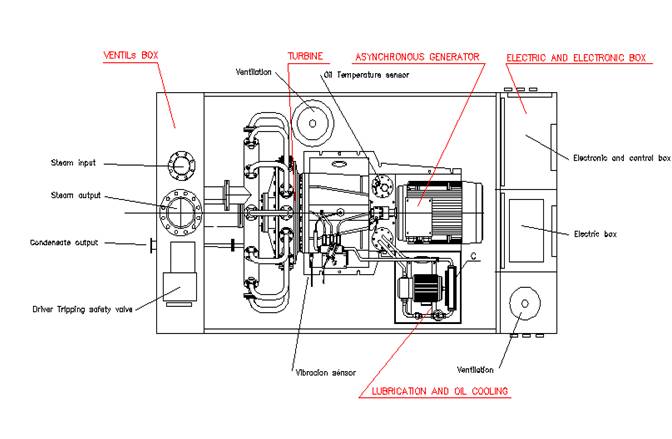

Patented turbine

Non-blade turbine wheel

Slow working revolutions of the turbine/ 3000 rpm /

Efficient alteration of the Velocity Head on the power in

turbine is min 95%

Turbine is not a pressure tank

Applications

Reduction turbine / electric energy production

Electric energy production in the prime or secondary

steam line

High end level of the components

LANDIS&GYR valves

Armatures made by TYCO company

Focus on the Safety and Reliability

Sensors made by Baluff

Tripping safety valve TYCO

Simple operation and control

Automatic computerized control system

touch panel for operation

Internet connection /optional/

Generator

Asynchronous generator

Certification

Steam and condensate connection based on DIN 2576

CE certification of the S2E module

S2E |

INPUT |

OUTPUT |

|||||

| Type | Capacity | Steam Inlet | Steam Outlet | ||||

| S2E50 | 50 kW | DN 40 | DN 150 | ||||

| S2E100 | 100 kW | DN 65 | DN 150 | ||||

| S2E150 | 150 kW | DN 100 | DN 250 | ||||

| S2E200 | 200 kW | DN 150 | DN 250 |

Sound Levels

| Characteristics | Specification |

| Standard | 80dB |

Net weight of machine with frame

| Characteristics | Specification |

| Max | 12 500 kg |

| Min | 1 500 kg |

Physical Specification (typical)

| Dimension | Size |

| Length | 7200 mm |

| Width | 2500 mm |

| Height | 3100 mm (Module itself 2400 mm) |

Service interval for bearings exchange

| Characteristics | Specification |

| Turbine | 25.000 hrs |

| Generator | 25.000 hrs |

The investment into an S2E Module creates for the customer the most

efficient profitability on the basis of the waste steam in the existing system.

QUICK RETURN on S2E INVESTMENT

Technopa GmbH provides a complete package for its customers, starting with

the optimal calculation of the technical solution, through the basic

engineering for the S2E placement, the S2E installation and the start up itself

with the technical and financial service.

TECHNOPA GmbH:

Hietzinger Hauptstr. 50

1130 Vienna, Austria

FN 364372t HG Wien

t: +43 1 877 0553

f: +43 1 877 8446

www.technopa.eu

office@technopa.eu